CNC Machining

quick guide

What is CNC Machining?

Milling

Vertical Milling

Like the drill press mentioned earlier, vertical milling operations have the tooling rotation running vertically (in the direction of gravity). A simple vertical CNC machine as seen in Figure 1 will have three axes where the tooling moves vertically; the table moves from the front to the back of the machine, as well as from side to side. These machines are common in many machine shops because they are cost-effective, simple to program, but still offer diverse capabilities.

Horizontal Milling

Multi-Axis Machines

CNC Turning

CNC Lathes

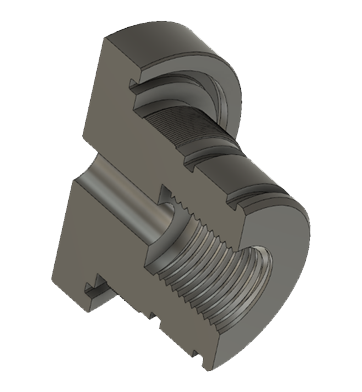

Like CNC milling, CNC lathes can use various types of tooling to create different features in round parts. These could be features like o-ring grooves, internal and external threads, face grooves, and so on. Lathes will also have a tailstock located opposite and in line with the chuck. The tailstock is used for holding a long workpiece or for completing various drilling functions. Figure 2 is a sectioned (cut in half) part that would be produced using a CNC lathe. Features include internal threads, external threads, outer diameter groove, inner diameter groove, and a face groove.

Live Tooling Lathes

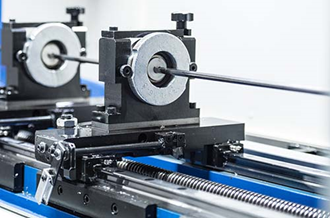

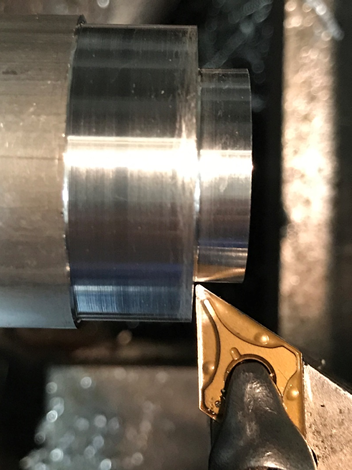

Live tooling lathes are a combination of a mill and a lathe. Like a lathe, there is a chuck holding and spinning the workpiece; however, the tooling is much more advanced. There are various tooling heads mounted to a turret. The turret allows for anything from standard lathe type tooling to mill type tooling. The added functionality makes it possible to dill and mill features off-center or perpendicular to the chuck rotation. Figure 3 is a photo of a live tooling lathe at Basilius.

Grinding

OD/ID Grinding

Surface Grinding

RAM EDM

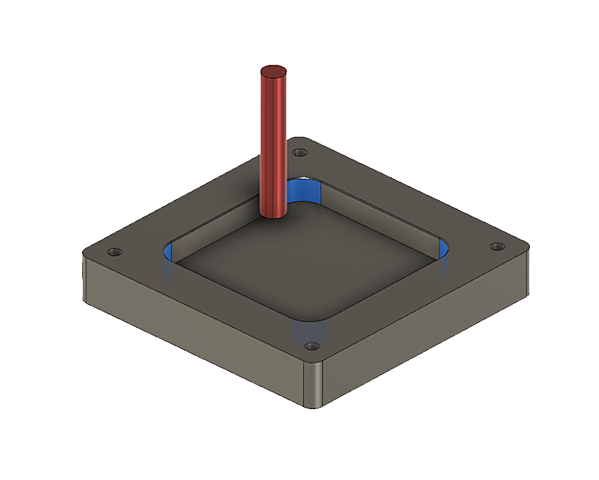

The RAM EDM, sometimes called a sinker, die sinker, or plunger, uses an electrode to produce the desired shape in the material via electrical current. First, a machinist will use 3D data of the desired part to design various electrodes around the part. The electrode is the negative (or opposite shape) of the desired shape in the material. Once the electrode is made, it is then placed into the RAM EDM.

The image below shows an electrode mounted inside of a RAM EDM machine. After the electrode is placed into the RAM EDM, a dielectric oil surrounds the material and electrode. The oil is a critical component in the process as it serves as an ionizer for the current, flushes out the material being removed, and cools the electrode and workpiece.

Compared to a CNC Mill or Lathe, material is moved relatively slowly when common/soft steels are used. The advantages of the EDM compared to standard CNC machining are the ability to machine extremely hard materials with ease, produce features that are either difficult or impossible on other equipment, and produce an array of textures.

Wire EDM

Drilling EDM

Deep Hole Drilling

One major aspect of any drilling operation is how deep a hole can be accurately drilled. The depth limit is typically measured relative to the diameter of the drill. This ratio is called the length to depth ratio. For example, a standard spiral drill is accurate to a length-to-diameter ratio of 5:1. If you were using that drill to produce a .500 diameter hole, a clean and accurate hole should be possible up to 2.5 inches deep. Going deeper is possible, but sticking to the 5:1 ratio is generally best in order to be safe, precise, and repeatable.

The most significant factors that limit the depth of any drilling operation are cooling and chip removal. In the case of the standard spiral drill—as hole depth increases, it becomes more difficult to get cooling to the cutting area and remove chips.

The unique design of the gun drill machine provides the ability to keep the cutting area cool and remove chips effectively at high L:D ratios. This is due to the high-pressure oil being directed right to the cutting surface. The oil is initially used for lubrication and cooling, but as the oil comes back out of the hole, it carries chips back out to keep the hole clean. The chips and oil are then collected in the base of the machine. The oil gets separated from the chips and recirculated through the process.

Another unique aspect of gun drilling is the way the drill is supported. In standard drilling operations, the drill is fixed to the spindle at one point on the drill. Therefore, the depth limit is set by the length of the drill bit. In gun drilling, the drill is supported at the beginning of the hole. During drilling, the drill moves through bearings and stays supported as the drill advances.

Honing

Materials

Plastics

- ABS

- Acetal

- Polypropylene

- Polycarbonate

Metals

- Low Carbon Steel

- Aluminum

- Brass

- Stainless Steel

- Tool Steels

- Nickel-Chromium Alloy

Simplification Equals Savings

Contours

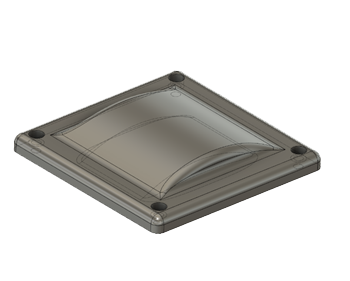

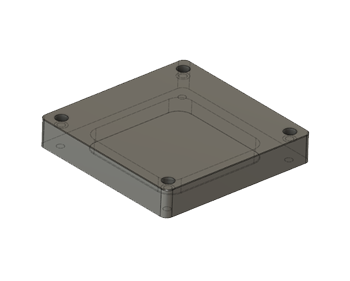

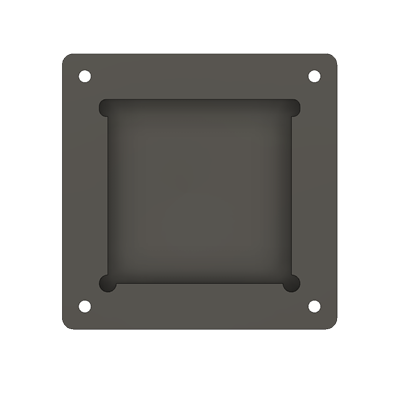

Contours are easy to create in CNC operations, but they require longer cycle times to produce. Unless a contour is needed for the part to function correctly, it is best to simplify the surfaces to save on machine time (part cost). Figure 6 shows the before and after of a part with and without a contour. Eliminating this contour could drastically reduce the cost of the component. You see the pocket on the underside of the part is simplified as well.

Fillets / RADII / Chamfers

Figure 8 shows a common tooling insert for a lathe (gold color). Nearly all of these types of inserts have a rounded (radiused) end. The radius helps to cut away material more efficiently but will also generate a fillet on inside corners during CNC operations.

If an inside corner for a turned component needs to be sharp, special “zero radius” tooling inserts will need to be used, which results in an added operation and tool setup.

As a general rule, it is best to allow for fillets on turned parts in order to avoid the added operation. In a later section, we’ll show you some design tricks to help you avoid the added operation.

Limiting Setups

Depth & Size

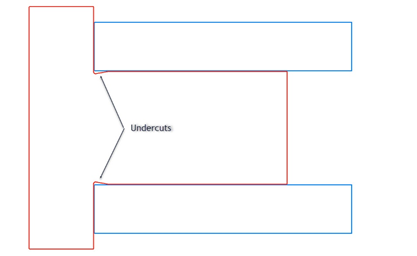

Work Holding

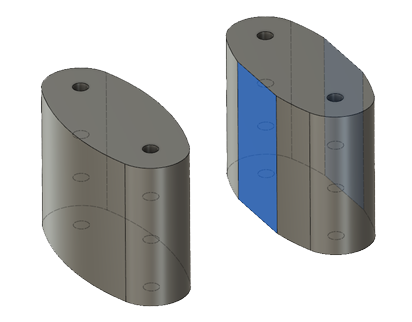

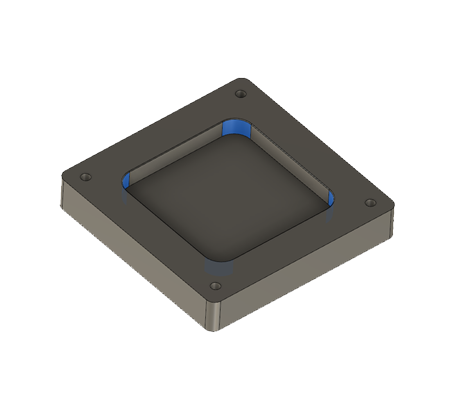

Operators need to be able to tell the machine where the part is. To do that, they need to locate something like a hole or a few details of the part. If a part is heavily contoured with no straight or parallel edges, it may be difficult or impossible to hold and locate. Below is a simple contoured part that could be easily CNC machined in a vertical mill from the top of the part. However, holding the part to get to the other bottom would be difficult for the part on the left. Adding two parallel faces (highlighted in blue on the right part) allows the part to be gripped in a vice and located in the machine. There are tricks like custom fixturing, but this adds extra set-up time that could otherwise be avoided.

Design Tips & Tricks

Eliminating a Corner Radius

As we mentioned earlier, the CNC milling operation automatically creates a radius on vertical inside corners. If your assembly requires a sharp corner, there are a few options available. The lower two corners in Figure 10 show the corners drilled out. The diameter of the hole is large enough that the vertical and horizontal walls are completely straight. The top two corners use a design feature that accomplishes a sharp corner with a slightly different design.

These features are designed around allowing a mating component to have a sharp corner. That is, something with sharp corners needs to fit into the pocket in Figure 10 above. If the mating component cannot be modified and the above design features are not possible, the corners can be EDM’d to a much smaller radius. As mentioned previously, this is an additional cost and set up that should be avoided

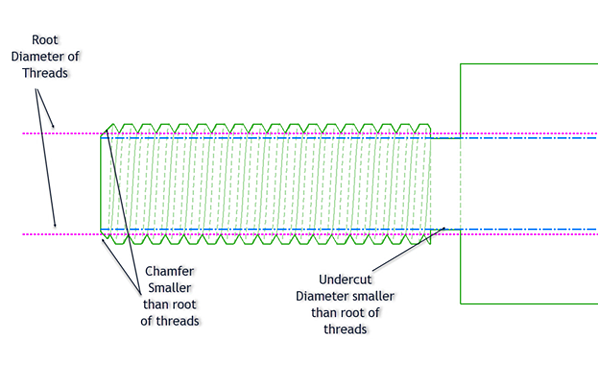

Turning Threads

Zero Inside Radius on a Turned Component

Non-Standard Fillets

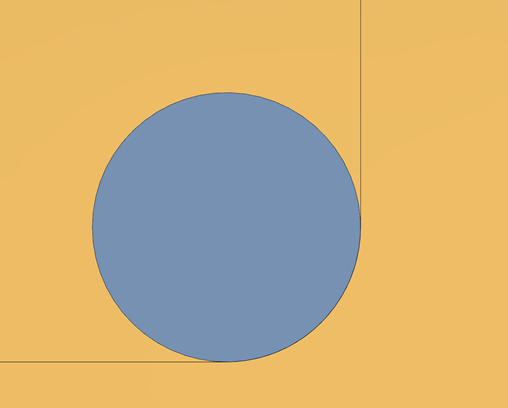

When designing radii on a part, it is best practice to make the radius a non-standard value. That is, instead of having a .250 corner radius, make it slightly over (.260). Doing this ensures that CAM software generates the radius with cutting equipment, rather than allowing a tool to engage fully in a corner. In Figure 13-A, a half inch cutter is fully engaged into a corner with a ¼ inch fillet. The excess contact area causes chattering, which produces a rough finish and may cut the part slightly undersize. Figure 13-B is zoomed in more and shows the difference in contact area when a corner radius .260. The difference in design is small but makes the CNC process more robust. If a fillet is specified to be ¼ inch, an operator may program it to use a smaller tool to avoid full engagement. Doing so adds another setup and another operation (increasing cost slightly).

Think Big

In general, smaller features take more time to make. For example, since a CNC milled pocket will generate an inside radius, it is better to have a radius at .260 than .100. In the example part shown below, the corner radii are highlighted in blue. The corner radius is .260 and therefore, can be produced by a half inch mill. That same tooling bit would likely be able to cut this entire part as well. If these radii were reduced to.135 , a 3/16 mill would be largest diameter tool able to produce the radius.

The smaller tooling may not serve much of a purpose beyond cutting the smaller radius. Therefore, the smaller radius would require the setup of another tool, a tool change, and additional programming. Keep in mind that design features like these are relative to the part design as a whole. If the part is small, then small features are unavoidable. The basic premise is that having lots of different design features that require several different types of tooling should be avoided when possible. It is also advantageous to keep sizes consistent throughout the part design.

Finishes

As Machined