AUTOMOTIVE SUPPLIER

FOR OVER 25 YEARS

Basilius has been a Tier Two automotive supplier for over 25 years. We understand the unique challenges that this industry presents to suppliers. Meeting customer cost, quality and timing expectations are critical to success in this industry. We have built a history of success. After all, we provide plastic components to Tier One suppliers serving almost every automotive OEM.

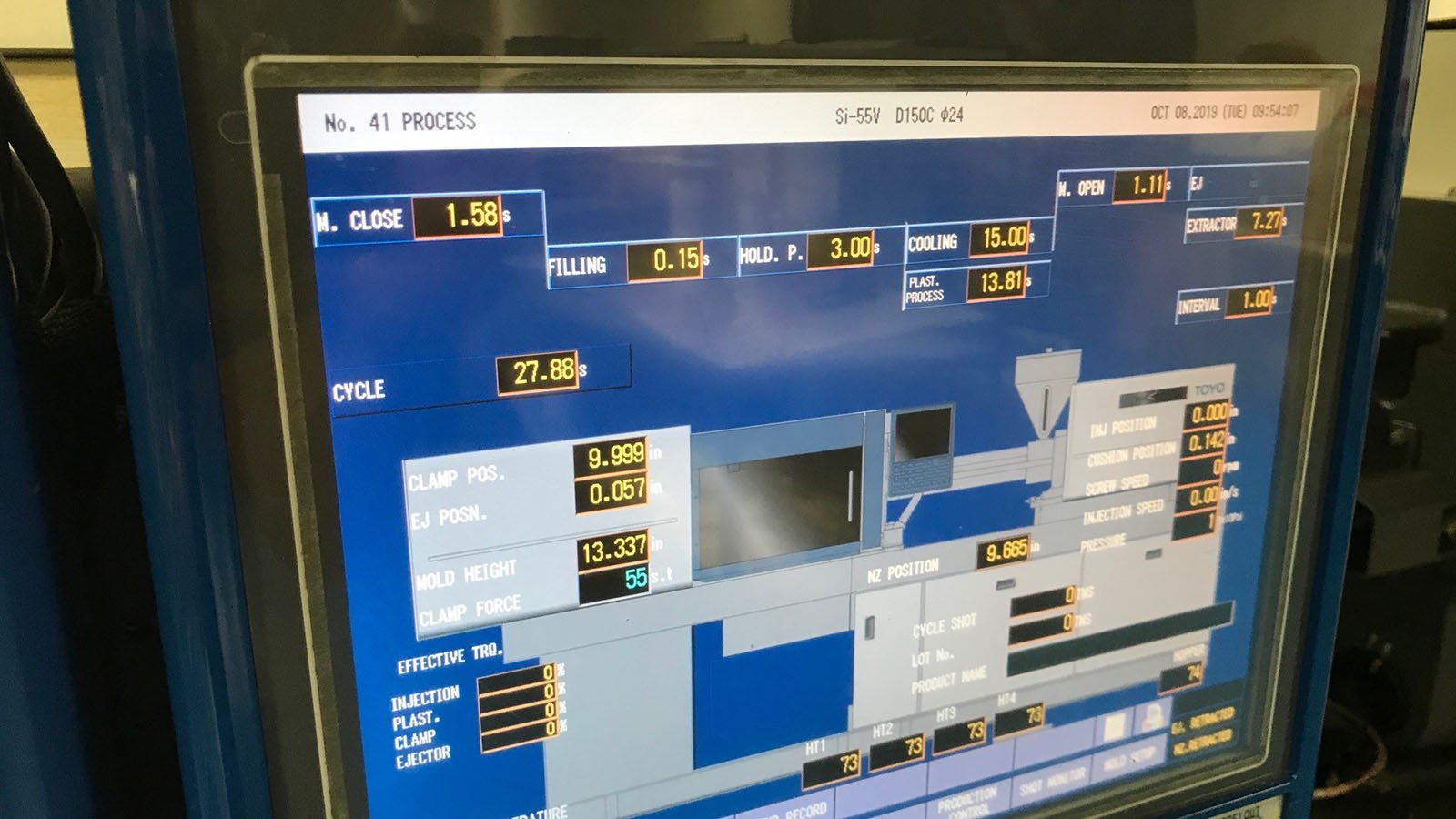

Injection Molding

past automotive projects

Over the years we have supplied a number of specialty injection molded parts for the automotive industry. Let us be your automotive supplier for your parts. What can we help you with?

- Insert Mold Window Lifts

- Oil Filter Screens

- Window Location Pins/Clips

- Window Brackets

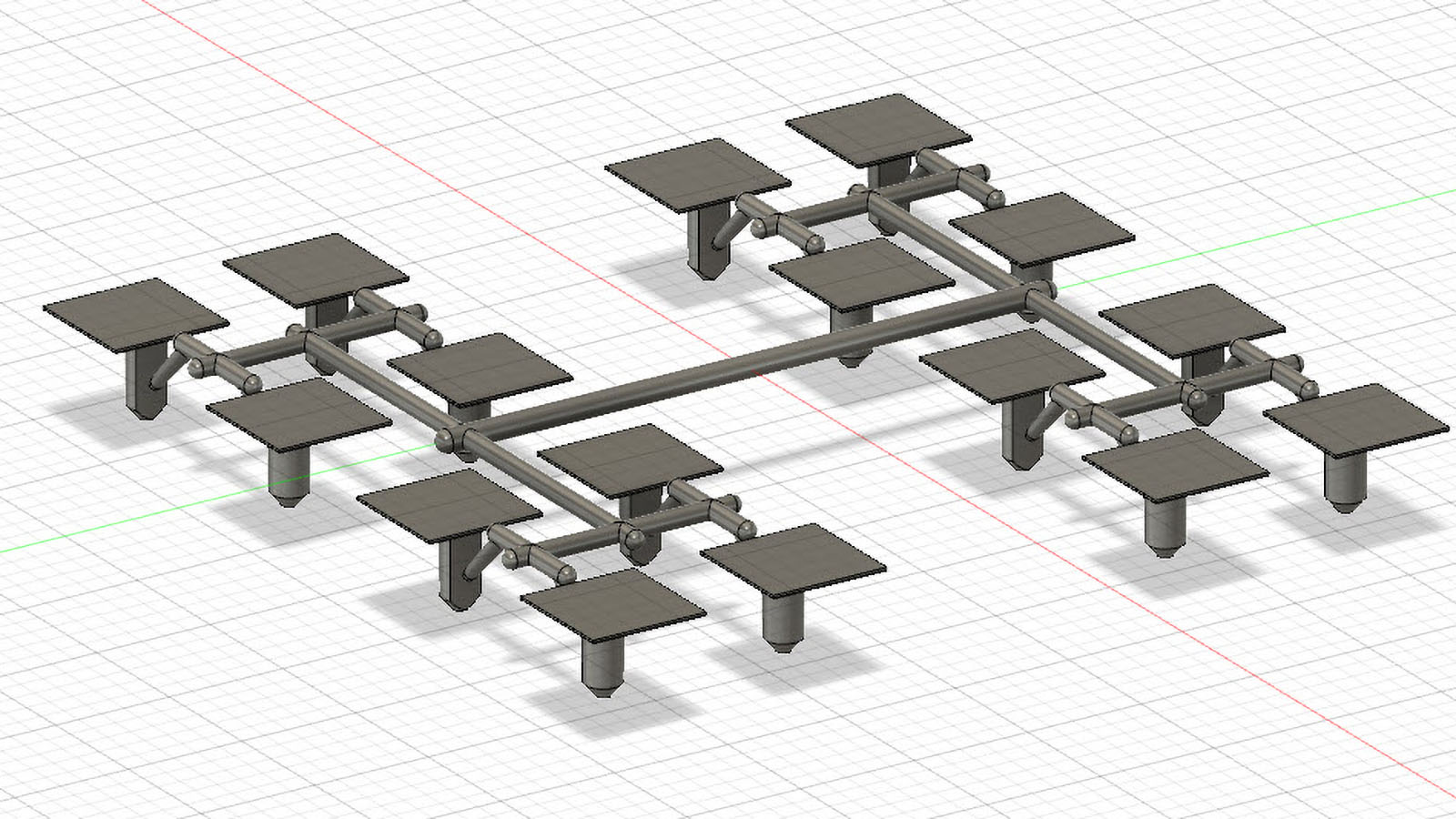

mold building

past automotive projects

Need a mold built from scratch? Not a problem. We have created plenty of high-quality molds for some really awesome parts.

- Door Handles

- Stereo Bezels

- Pillar Covers

- Fuel Doors

why choose basilius

For your NEXT Automotive Project

I have been working with Basilius Tool since 1997, Basilius builds high quality Injection Molds. They stand behind their work 100%, they believe the tool is not finished until the customer is happy. We at Key Plastics / Novares have been using Basilius for New Tooling, Engineering Changes & Tool Repairs and Refurbishing. Basilius has always been an excellent supplier for us at Key / Novares.

Gary J.

Tooling Buyer / Key Plastics / Novares

Understanding the Injection Mold Process

Here we look at the injection molding process and the different methodologies for controlling it.

Surface Finishing The Complete Guide

Surface finishing plays an important role in the manufacturing process. Let’s discuss popular techniques and applications.

Understanding the Cavitation Cost Benefit Analysis

Cavitation can have huge implications on both piece price and mold cost. See how we can do a cost benefit analysis to find the right fit.