Our Expertise

Will Keep You Competitive

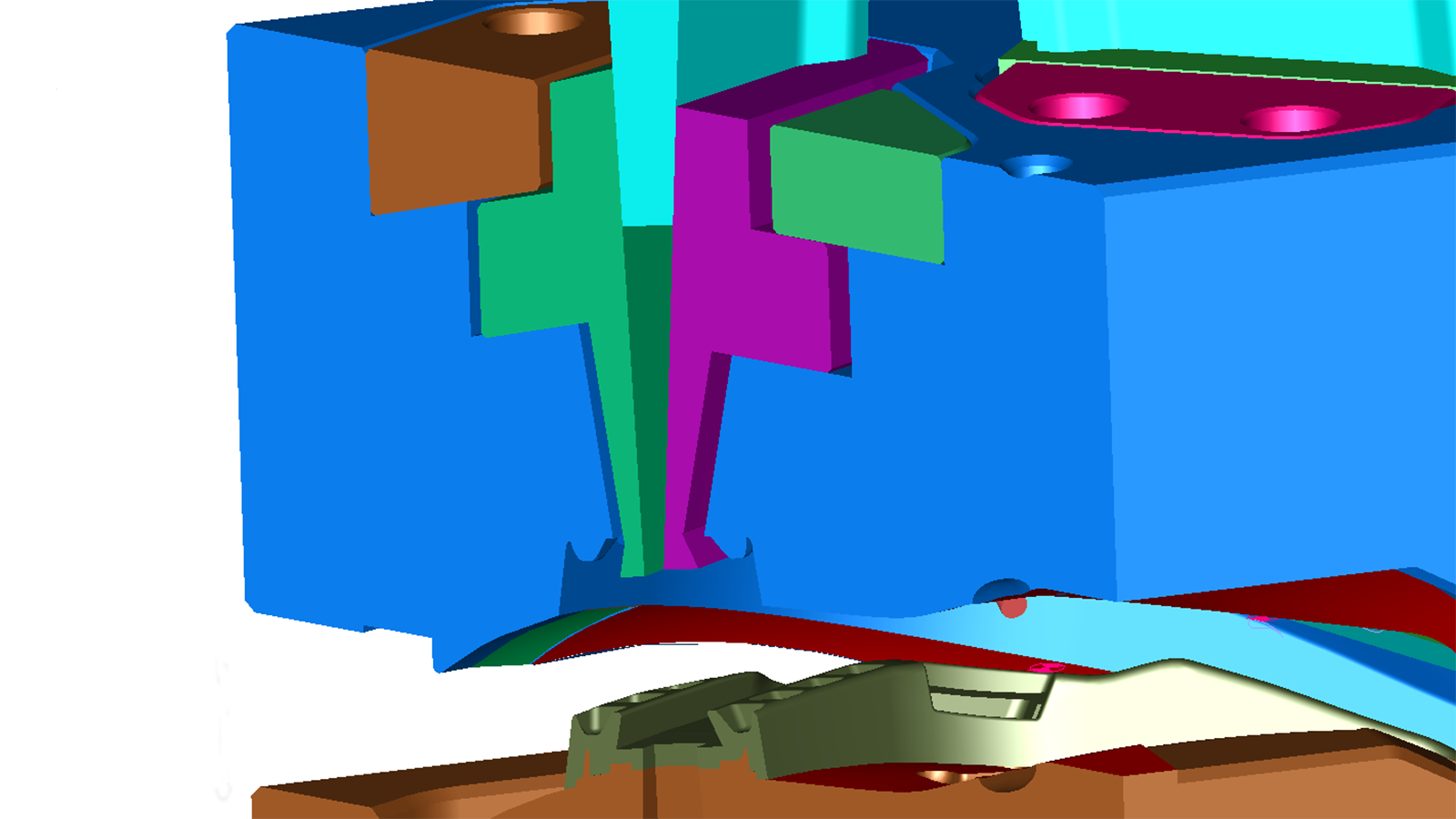

Like the needs of our industrial customers, consumer product development often presents opportunities for us to utilize our expertise and mold flow simulation tools. Cost savings opportunities through design and material considerations are key to helping our customers be cost-competitive in a tough marketplace.

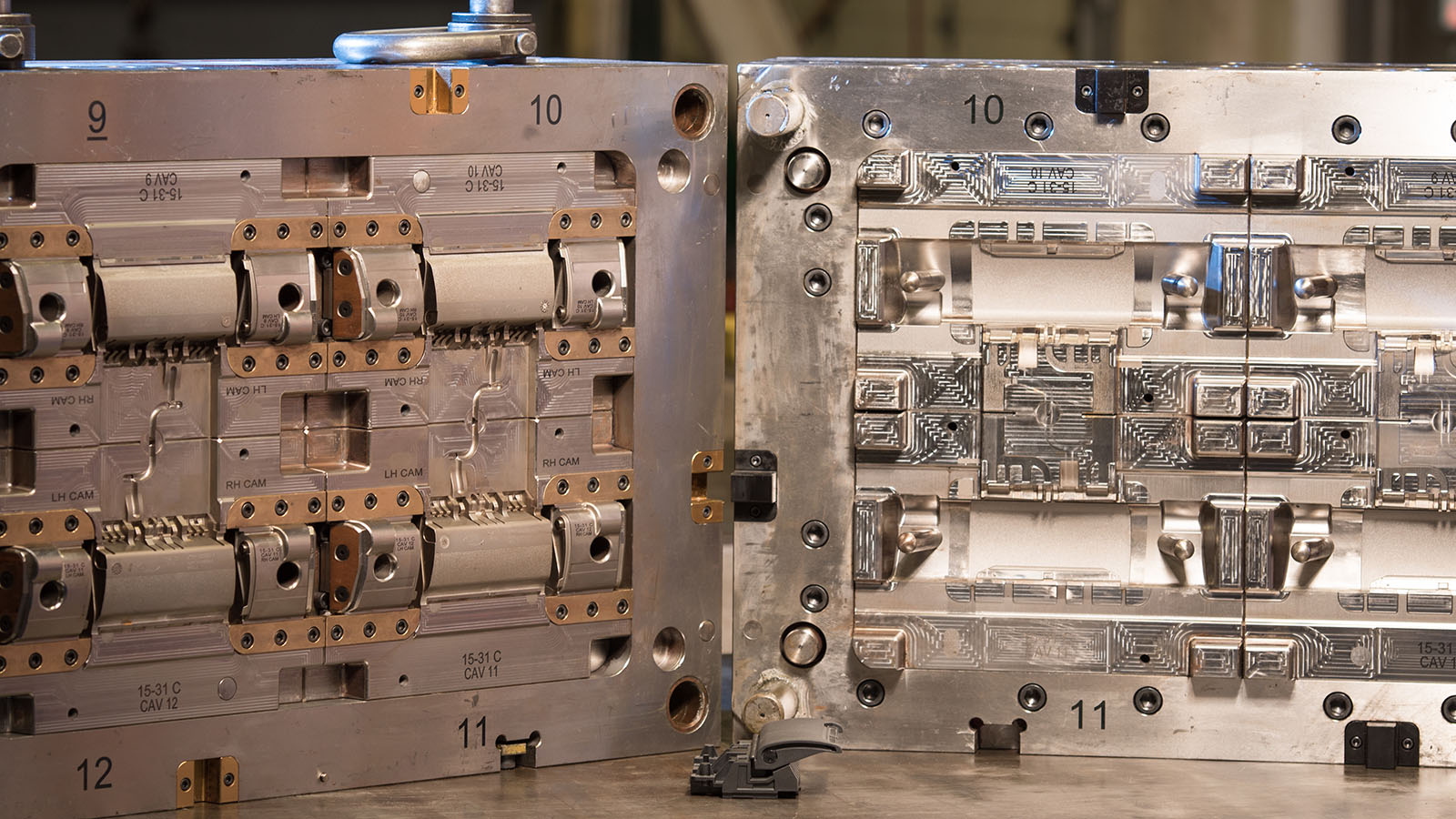

Injection Molding

Past Consumer Products

Every consumer product presents a unique challenge. With decades of experience, we face these challenges head-on and help produce some amazing products for mass consumption.

why choose basilius

For your Consumer Products

Understanding the Cost of Injection Molds

The cost of injection molds vary based on the part and the application. This post will help you understand the contributing factors to the cost of a mold.

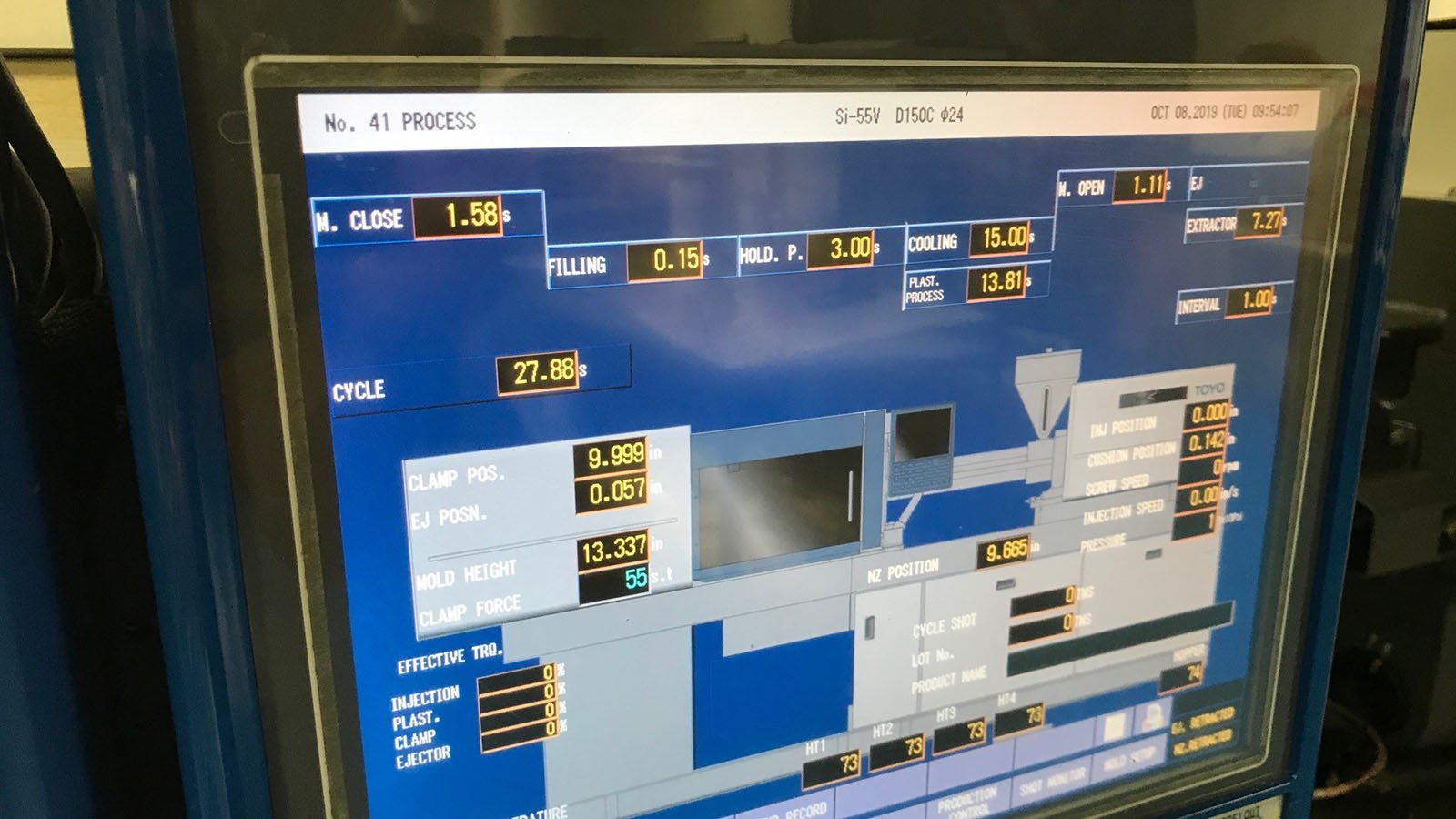

Barrel Residence Time Calculation

Residence time can have a large influence on part quality and process consistency. Check out how we calculate it to match a mold to a press.

Cavity Side Dovetail Pull Action

This part is for a military application and required two dovetail features on the A side of the tooling.