cREATED & CRAFTED

MOLD DESIGN & DEVELOPMENT MATTERS

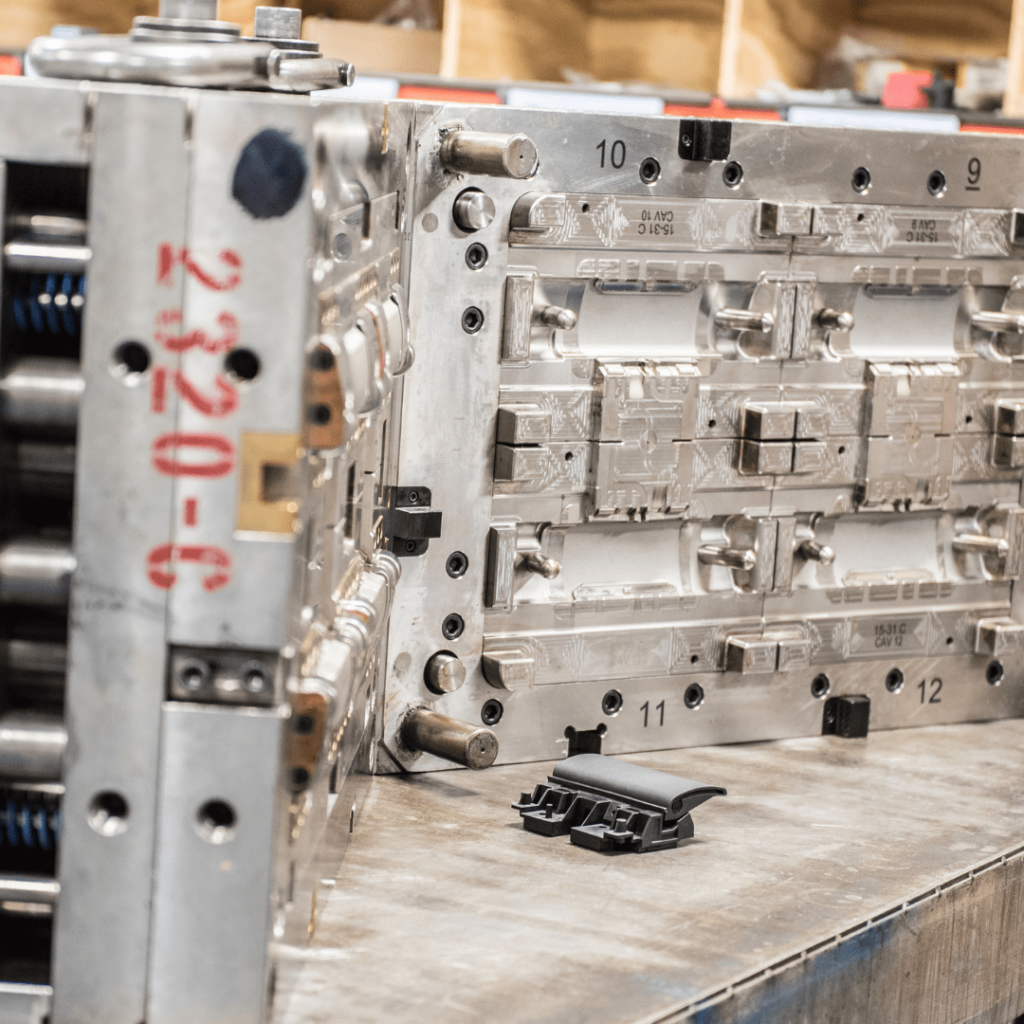

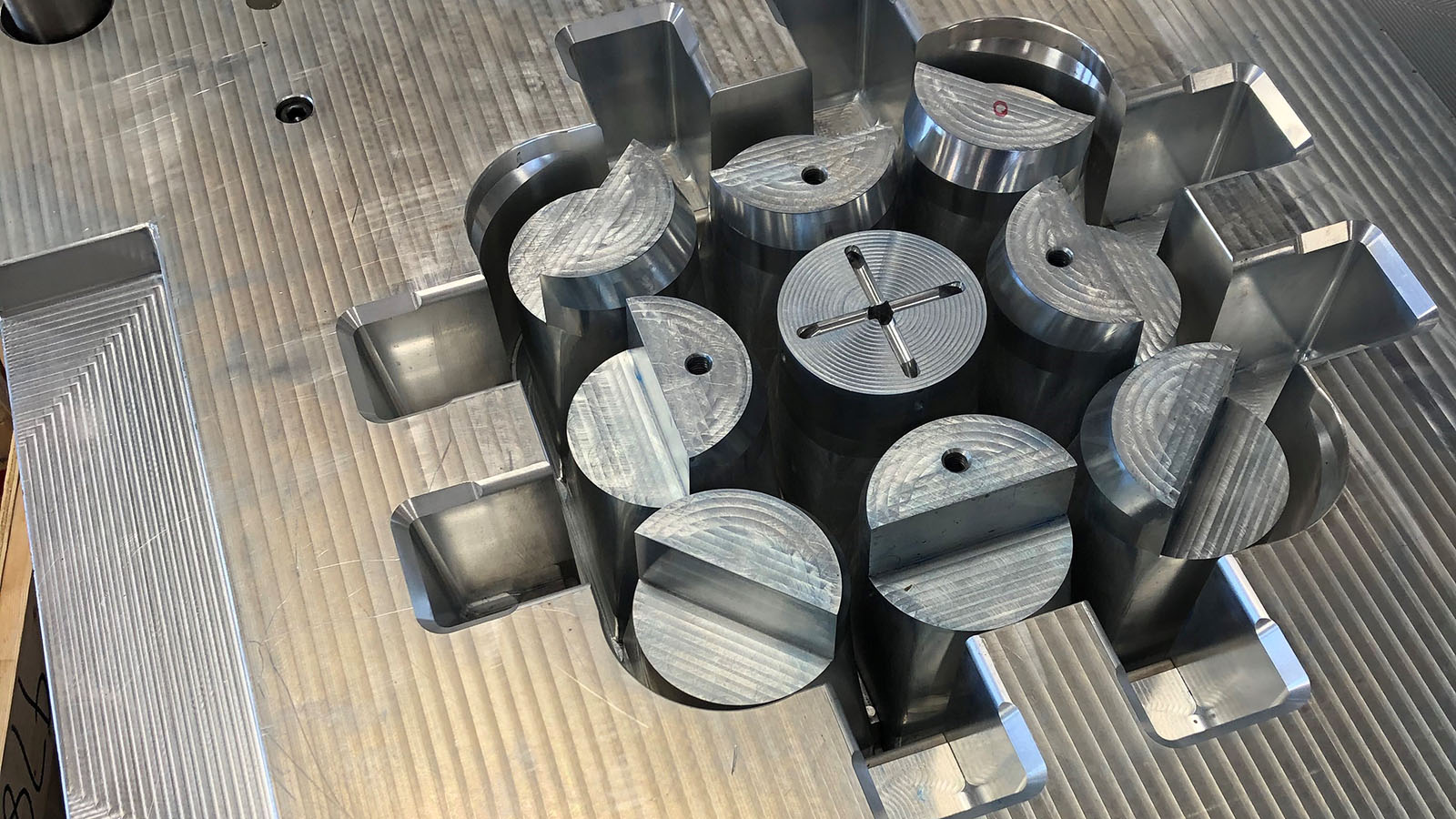

The quality of the part can’t be greater than the least of its parts. It’s simple: the precision of the tool is the key to the quality of the part. Mold building is an art. That’s why we build and test our tools to the most exacting quality standards. Whether you need a repair, revision, prototype or high volume multi-cavity production tool, we’ll turn it around quickly and accurately.

DESIGN

The Art of Mold Building

part design

Bring us your idea and we will take it from concept to a workable design. With Basilius it is just that easy.

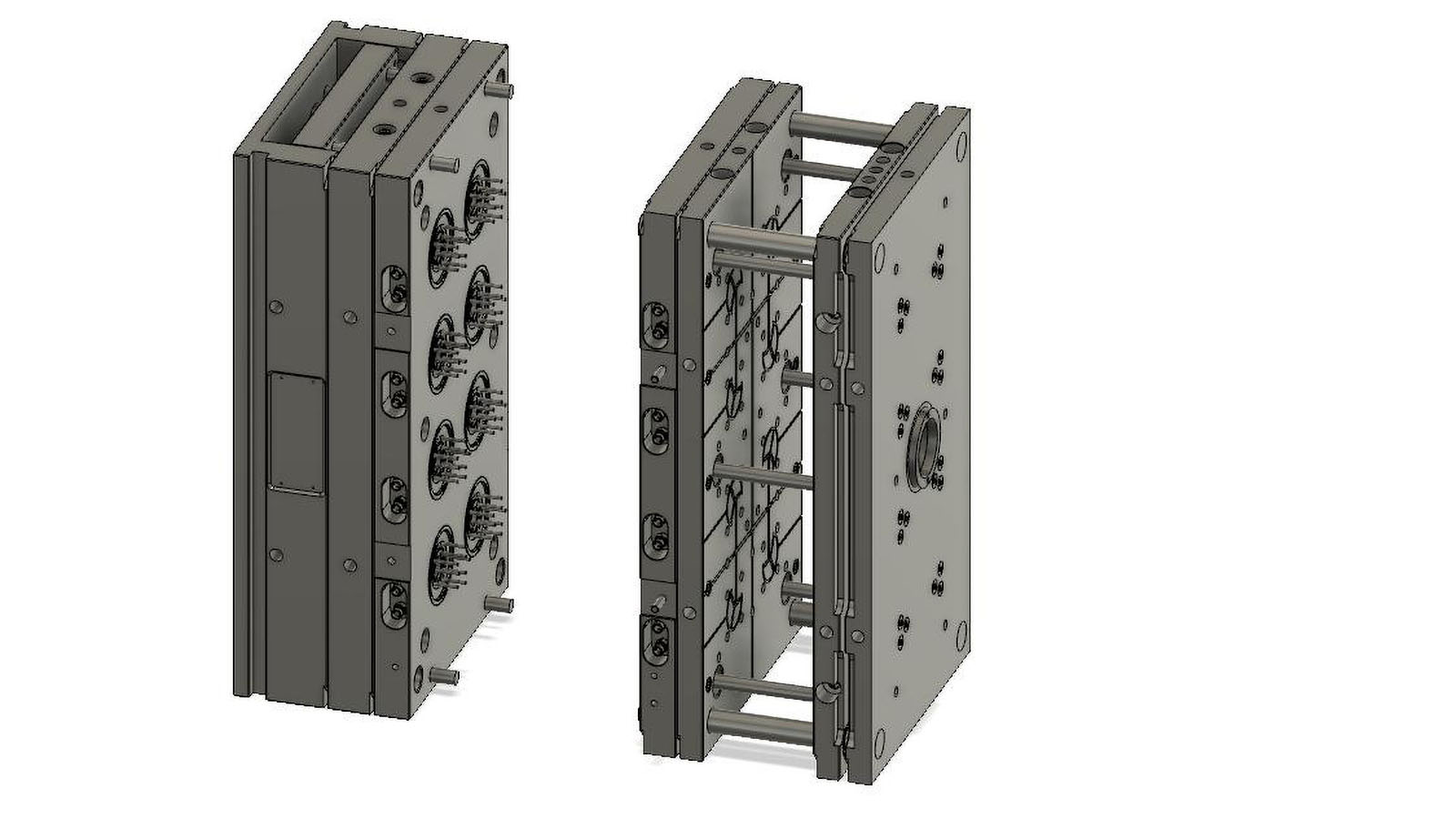

Tooling Design

At Basilius, we factor quality, efficiency, and durability into the equation. During the mold design phase we analyze every detail to anticipate potential problems. Leaving you with an easy to operate and trouble-free design.

pURPOSE bUILT sOFTWARE

You will find KeyCreator software on nearly every Basilius computer. KeyCreator's solid-based modeling creates mold designs, which become our road map for every tool build.

ANALYSIS

TESTING THE DESIGN

MoldFlow Analysis

Simulating plastic flow is the front-end to our mold designing process. Performing multiple what-if scenarios gives us the information we need to achieve quality molded parts.

Design for Manufacturing

DFM portrays the intent of the mold design. Some of the design items considered include; parting lines, gating, ejection locations, action, draft analysis, and part wall section analysis.

In-house tooling trial

The tool debugging phase of mold validation occurs at our facility ensuring that the tool is production ready when it arrives at your door.

Industries sERVED

Bringing Your Projects to Life

We pride ourselves on our versatile expertise and commitment to excellence, which allows us to serve a spectrum of industries. We specialize in mold building and injection molding, enabling us to deliver superior quality products with unparalleled precision and efficiency. By harnessing cutting-edge technology and leveraging our vast industry knowledge, we consistently exceed expectations and drive innovation across the industries we serve.

» Insert Molded Window Lifts

» Oil Filter Screens

» Window Brackets

» Window Location Pins

» Overmolded Screw Plungers

» UV Phototherapy Combs

» Vessel Preparation Components

» Power Washer Spray Handle Assemblies

» Well Caps and Fittings

» Fluid Transfer Fittings

» Goggle Grips®

» Handy Safety Knife®

» Accessory Rail for Ballistic Helmet

» Overmolded Pistol Grip

» Insert Molded Buttstock

Get HIGH quality injection molds

Let our expert team assist with your mold building project

why choose basilius

For your Mold Building Project

We’re expert mold builders. Whether you need a quick prototype mold or a quality high-volume production mold that lasts, we have you covered. Our mold manufacturing and repair process is second to none and will leave you 100% satisfied with the result. Not quite sure what you need? That’s fine too. Fill our our simple mold building quote form. We’ll contact you and happily guide you through the entire process.

ANCHOR UNITED LLC

A MOLD BUILDING CASE STUDY

Anchor United LLC provides consultation and design while working with its customers to develop and produce a variety of projects. Occasionally those projects fall outside of their in-house capabilities, and that’s where owner Ray Niscior elected to partner with us. It is the perfect pairing. But don’t take our word for it…

Ready to start your project?

Our team of experts are ready to assist you

Mold BuildING Resources

Learn More From OUr Expert Articles

Mold Repair or Replacement?

Use this guide to help decide if you should keep repairing an old mold or replace it all together.

Designing for Molding: Types of Plastics

There are thousands of plastics available to injection molders. Learn about the broad categories of materials.