The FCS workholding system was created over a decade ago and is now deployed at hundreds of shops around the world. We bought into this system when we purchased our Makino A61nx in 2018. Combining the efficiencies of a pallet changing horizontal mill and the FCS system has helped us decrease tooling lead times by reducing setup times and optimizing spindle on time. So how does it work?

Traditionally machine operators would indicate a block into a machine to make sure the block is straight and to find X/Y center. Once that is set, the workpiece was either clamped down to a table, held with magnets, or clamped in a vice. These systems still have their place, but doing this several times a day isn’t efficient and is subject to operator error.

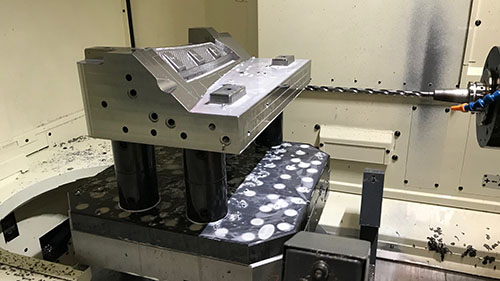

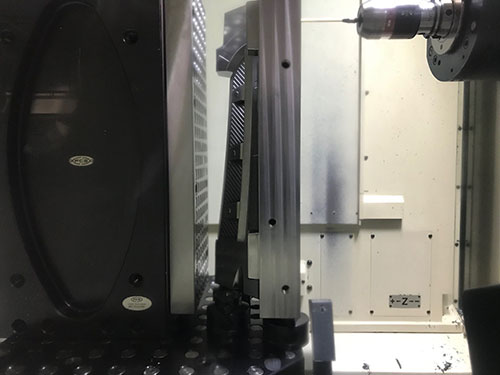

The FCS system is a grid of clamping points on a plate. The machining center and CAM software “knows” wear the grid system is so that a workpiece can be clamped anywhere on the grid. The machine operator plans where the clamp system will be used, so they never have to indicate or center their workpiece. Once the workpiece is installed onto the clamping system, the machine can start cutting with no delay. Taking it another step further with the pallet changer, we can get the next set of components clamped and ready while another one is being machined. This virtually eliminates set up time by overlapping it with machining time.

The FCS system does require features in the workpiece for their clamps to works properly. These are designed into the blocks in advance and machined traditionally when roughing the first side of the block. The clamp features are designed to be inbound to one side of the block allowing the machining center access to multiple faces. In the case of our A61NX, we can process four sides of a block. Once complete, the operator can use additional FCS components to flip the block 90 degrees, providing access to other sides. Again, without centering the block. Here are some examples of how we are using FCS work holding every day at Basilius.

You may be wondering, what does this mean for the customer? This means a reduction in lead time. At Basilius, we’ve realized that it’s just as important to understand what isn’t going to change as it is to understand what is changing. Our customers don’t want to pay more for their tooling, get it slower, or have it built with lower quality standards. The pressure to build quality tooling both cheaper and faster is simply not going to change. The FCS system, coupled with the Makino A61NX, is how we are meeting and exceeding the demands of our customers.